Numeric Input tests are used to enter variable data in an inspection.

|

Contents [Hide] |

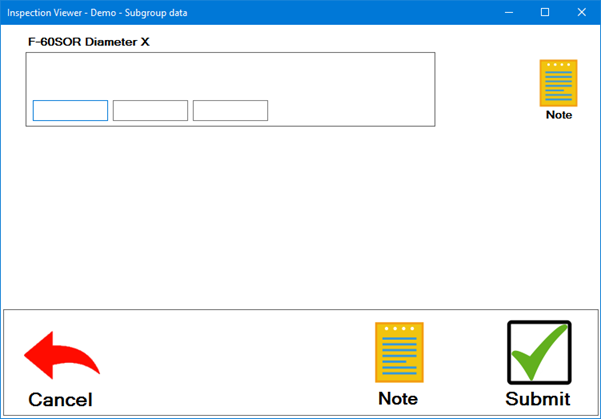

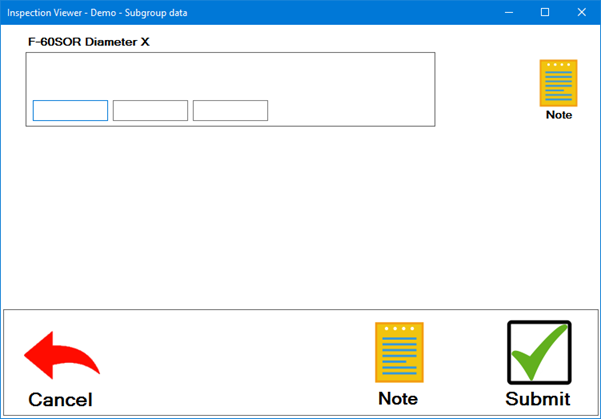

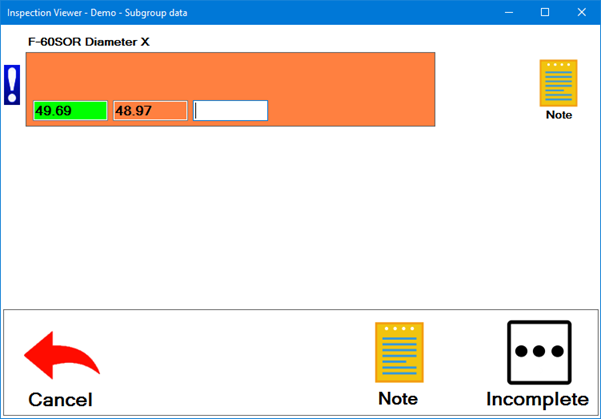

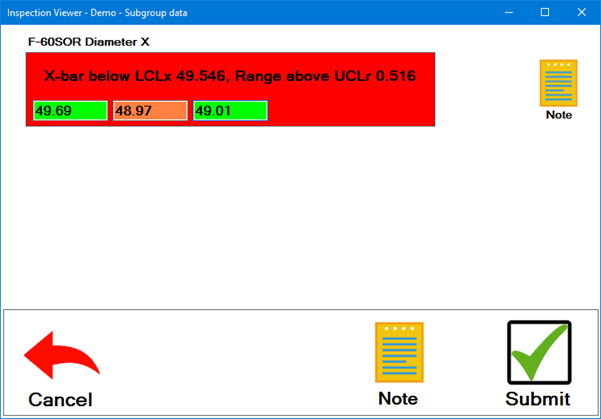

This sub-inspection contains a Numeric Input test for an SPC standard with a subgroup size of three.

The inspector enters measurement values for the specified SPC standard (F-60SOR Diameter X). The inspector can move between the measurement fields by clicking in them or by pressing the TAB key or Enter key.

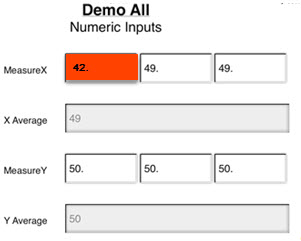

Upon leaving a measurement field, GainSeeker will check that value for individual real-time failures, and your configuration settings for colors will be applied.

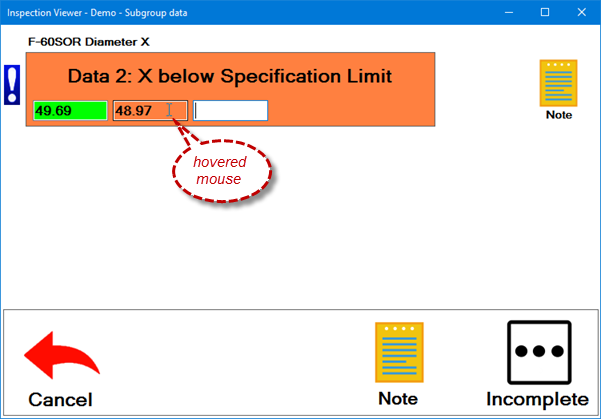

To view the failure status of any measurement field, hover your mouse over that field:

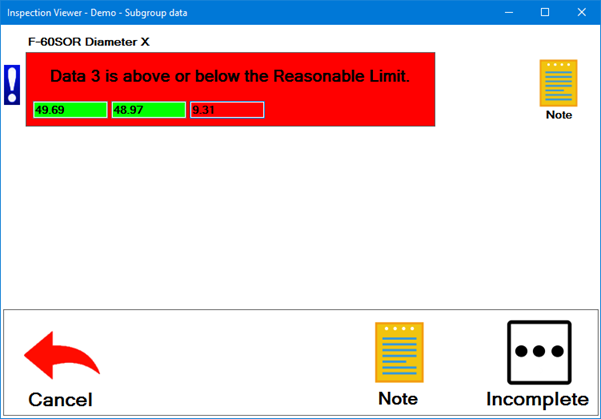

If a measurement is outside the reasonable limits, you must correct the value before you can submit the data.

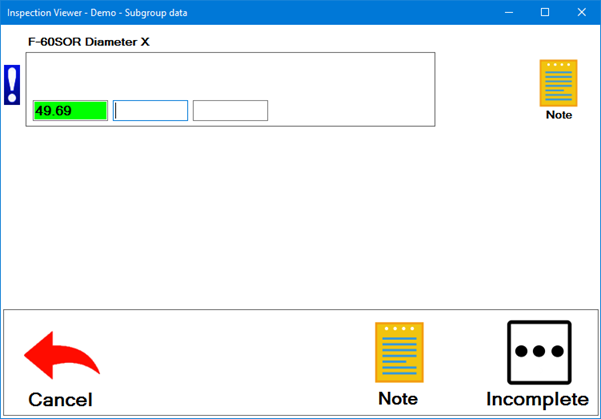

If the subgroup cannot be completed, you may enter an asterisk ( * ) in place of the missing measurement. For more information, see Entering an incomplete subgroup.

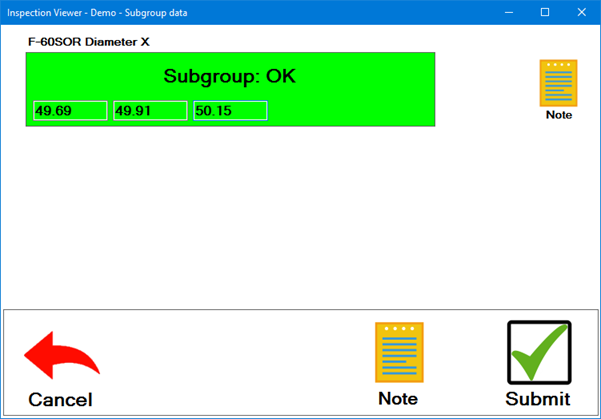

After the subgroup is completed, GainSeeker will check for subgroup real-time failures, and the subgroup container will be colored based on your configuration settings for colors.

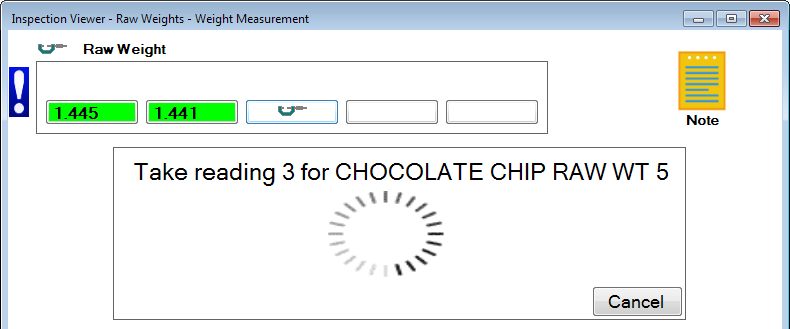

If your Inspection is configured for RS-232 data entry directly from your measuring device to the PC, you may need to use some of these features:

If your measurement field looks like a gage button, click it to begin direct data entry from your measuring device.

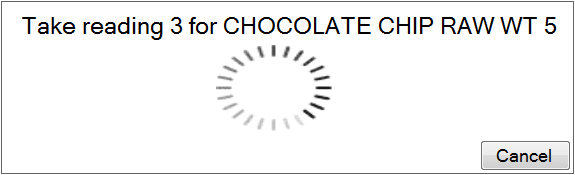

If you see a window like this, use a "Send" or "Print" button on the device (or perhaps a footswitch or handswitch attached to the device) to send a measurement to the computer.

If you need to enter a data value via keyboard instead directly from the device – for example, if the device is broken or out for service – you can press CTRL+K at this type of prompt:

The prompt window will change to look like this:

At this Keyboard Input prompt, you can type a measurement, press CTRL+K to change back to RS-232 mode, enter an asterisk ( * ) in place of a missing measurement, or click Cancel to pause data entry.

If you need to re-run a measurement, click on the data cell you need to re-measure and then delete the bad measurement. The RS-232 prompt or keyboard prompt will automatically display for you to re-enter the correct value.

Depending on how the inspection was designed, the inspector can enter a value by:

When any of the individual points in a Numeric Input test has a failure, the background of only that value box changes to red.