Requirements for collecting OEE data

Special prerequisites and requirements apply when collecting OEE (Overall

Equipment Effectiveness) data.

Prerequisites to collecting OEE data

1. Create OEE traceability

fields

Use the System Administration module to create five new traceability

fields for raw OEE data:

Select five consecutive traceability fields (for example, fields

7–11) that are

not previously used.

Assign a label to each of those traceability fields in this

order:

Available Time

Scheduled Time

#Good Parts

#Total Parts

Ideal Cycle Time

For detailed instructions on creating traceability labels, see Adding

traceability field labels.

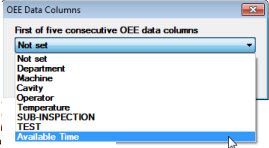

2.

Change an OEE Statistic setting

Use the System Administration module to designate the first of these

new traceability fields for special use as OEE data:

In the System Administration module, navigate to this setting:

Configurations tab | configuration name | Statistics

| OEE | First

of five traceability columns where OEE values are stored =

Right-click the First of five

traceability columns where OEE values are stored = setting,

then choose the new Available Time

traceability label.

Then click OK.

Requirements for entering OEE

Data

Use one of the many GainSeeker data entry options - PC Collect,

SPC Data Entry, DMS Data Entry, etc. - to enter OEE data for analysis.

Store OEE data as DMS data

records (not SPC data).

Important data fields are the Date/Time stamp, the new traceability

fields you added (above), and other traceability fields.

Date/Time

stamp

This relates to the frequency of data collection and determines

the smallest unit of time that you can use for comparing OEE values

- every 5 minutes, every 30 minutes, every hour, every day, etc.

For example: if you want the ability to calculate separate OEE

numbers for increments as small as every 30 minutes, then you

need to enter data records that are timestamped 30 minutes apart.

Also, each timestamp should fall within the time period it represents

- e.g., for OEE data from 10:00:00 - 10:30:00, the data record

should be timestamped between 10:00:00 and 10:29:59.

New

traceability fields

Available Time:

The length of time*

that the process was actually producing parts. For example,

if you are storing time values in Minutes, and the process

ran for 5 hours, then you would enter 300

(the number of minutes). This number should not include any

time that the process was unable to produce parts - either

for scheduled reasons (see below) or for unscheduled reasons

such as machine setup and changeover, equipment malfunction,

or material shortages.

Scheduled Time:

The length of time*

that the process was scheduled for production. For example,

if you are storing time values in Minutes, and the process

was scheduled to run for 8 hours, then you would enter 480 (the number of minutes).

Any scheduled downtime - preventive maintenance, employee

lunch breaks, etc. - should not be included.

#Good Parts:

The number of parts that were produced without defects (first-pass

yield). Reworked parts should not be included.

#Total Parts:

The total number of parts produced within the set time period

(good parts and bad parts).

Ideal Cycle Time:

The length of time*

to produce one part, when the process is running as fast as

it was designed to perform. For example: if you are storing

time values in Minutes, and your process is designed to produce

240 parts per hour, which is 4 parts per minute, or 1 part

every 15 seconds, then you would enter 0.25

(the number of minutes to produce one part).

*

The Available Time, Scheduled

Time, and Ideal Cycle Time

must all be entered with the same unit of time. Minutes are most common,

but you can use Seconds, Hours, etc. - as long as you use the same unit

consistently.

Other traceability fields

In addition to the OEE-specific traceability fields, your OEE data

records can also store information in the other traceability fields.

This will allow you to group OEE metrics by other traceability

values - e.g., by part family or work order - instead of (or in

addition to) analyzing that data by time period.

(optional) You may

also enter "typical" DMS data in these records - sample

size, number of good units, number of nonconforming units, defects

and counts. The OEE charts will not analyze this information,

but you can still use DMS charts to analyze this data.

In particular, consider setting up defects for Availability issues

such as machine setup and changeover, equipment malfunction,

or material shortages. During data entry, you could flag any downtime

events with the corresponding defect, and enter the number of downtime

minutes for that downtime event as the defect count. This ultimately

allows you to perform Pareto analysis on the downtime defects in your

OEE data.

You could attempt a similar approach for Performance issues. Or, if

these are too difficult to identify (and they often are), you could

still set up a "Performance Loss (Minutes)" defect and enter

the number of minutes lost due to slow performance. For every OEE

data record, this can be calculated as Available

Time - (#Total Parts * Ideal

Cycle Time) , with the caveat that this number cannot be less

than 0.

See also