This topic details the Performance metric of the OEE (Overall Equipment Effectiveness) formula: OEE =Availability x Performance x Quality

The Performance submetric of the OEE metric represents the percentage of time the process takes (the actual cycle time) related to the time the process should take by design. Simplified, it indicates how much slower a process is than it should be.

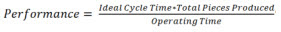

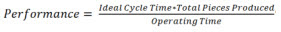

The Performance ratio is calculated based on Ideal Cycle Time.

Ideal Cycle Time is the best time under ideal conditions that you can expect to manufacture one product. This is also sometimes called the Theoretical Cycle Time.

The Total Pieces Produced is the total number of pieces produced without regard to quality for this metric.

Operating Time is the time the process was operational.

Like the other components of OEE (Availability and Quality), the Performance ratio is reported as a percentage.

Actual Operating Time = 338 Minutes (Total shift time [480 Minutes] less scheduled breaks [30 Minutes], machine setup [95 minutes], and other down time [17 minutes]).

With two more pieces of information, the Performance metric can be calculated:

Ideal Cycle Time is one unit produced every .25 minutes (15 seconds).

Total Pieces produced: 1187

Performance = (Ideal Cycle Time * Total Pieces Produced) / Operating Time

Performance = (0.25 * 1187) / 338

Performance = .8779 (Multiply by 100 to express in percent = 87.8%)

Example of an OEE Performance Chart