This topic details the Quality metric of the OEE (Overall Equipment Effectiveness) formula: OEE =Availability x Performance x Quality

|

Contents [Hide] |

There are two common formulas GainSeeker can use to calculate Quality:

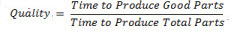

The GainSeeker default setting—measuring quality by time producing parts: Quality = Time to Produce Good Parts / Time to Produce Total Parts.

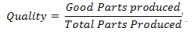

An alternate setting—measures quality by parts: Quality = Good Parts Produced / Total Parts Produced. You can set this as the default in your GainSeeker System Administration module.

A common method for measuring Quality is by yield—the percentage of produced good parts relative to the total number of produced parts. However, OEE is a measure of overall equipment effectiveness—or efficiency—which relates more to optimum or efficient time use in manufacturing first-pass yield. The formula that GainSeeker uses to calculate the Quality metric takes the time lost in producing bad parts into account. You can change the setting to a formula that measures yield detailed below in this topic.

This is the GainSeeker default formula for calculating Quality:

This setting is a more accurate formula for measuring Quality when different product types or similar factors are included in the Quality percentage. That is because the formula that measures yield depends on Ideal Cycle Times—the optimum, expected time it takes to produce single, specific type of part under ideal conditions, which tend to vary widely between product types as shown in the table below.

Quality can also be represented as the percent of good parts that were produced relative to the Total Parts Produced. Good Parts Produced is defined as only the parts meeting first-pass yield among all the parts produced during the set time period. Reworked parts are not included.

In five hours Part type A produced 1,200 parts of which six were bad. The Ideal Cycle Time for Part type A is .25 minutes (four parts per minute). In five hours, Part type B produced five parts, of which one was bad. The Ideal Cycle time for Part type B is 60 minutes (one part per hour).