SPC Chart Options

The SPC Chart Options window

lets you configure charts to display on the current sub-inspection. For

information on opening this window, see Setting

charts to display in inspections.

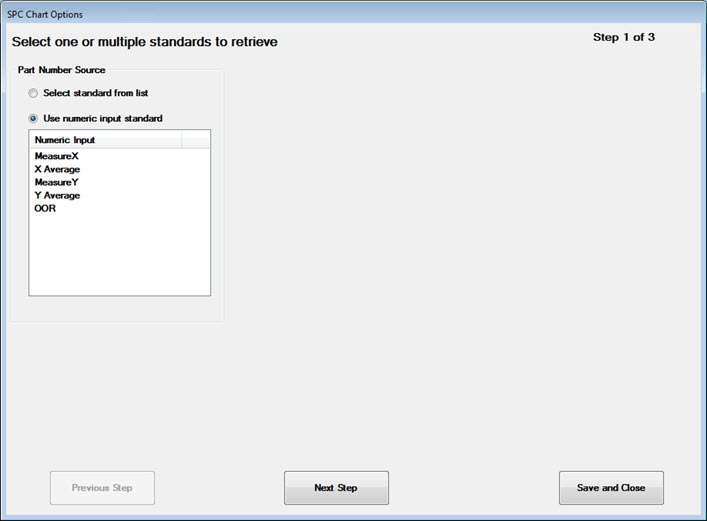

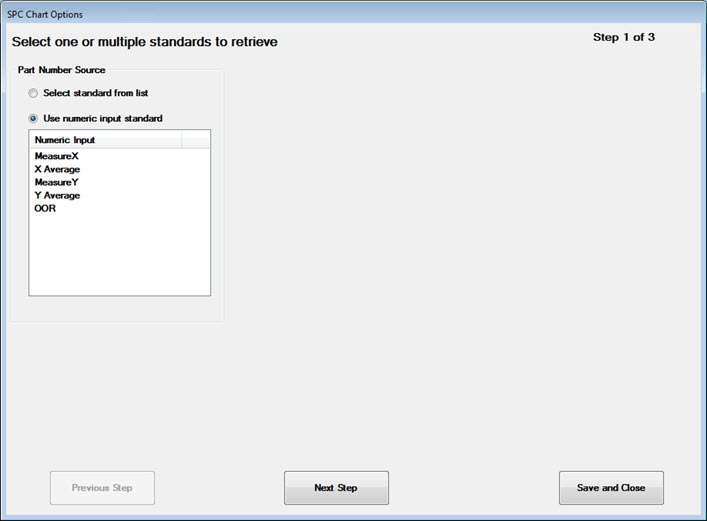

Step

1: Select SPC standards for the retrieval

If you want this sub-inspection to chart

multiple standards with the same chart types and chart settings (date

period, filter, statistical settings, etc.), you can use this step to

select all those standards at once –

beginning with the Part Number Source:

Select standard from list:

Use this option to select any standard(s) for data entry charts

– regardless

of any Numeric Input tests in the inspection. For more information,

see Selecting

Part Numbers or Processes.

Use numeric input standard:

Use this option to select the Numeric

Input test(s) in this sub-inspection as the source for your

standard. Click the Numeric Input test name(s) to chart for this

sub-inspection.

Note: If you copy and paste

a sub-inspection that is configured to chart one or more numeric

input standards, you will need to re-select the standards for

these charts in the new copy of the sub-inspection. This is because

the numeric input tests in the new sub-inspection will have different

TestIDs from those in the original sub-inspection. A reminder

message will be displayed when you copy and paste such a sub-inspection. Note: If you copy and paste

a sub-inspection that is configured to chart one or more numeric

input standards, you will need to re-select the standards for

these charts in the new copy of the sub-inspection. This is because

the numeric input tests in the new sub-inspection will have different

TestIDs from those in the original sub-inspection. A reminder

message will be displayed when you copy and paste such a sub-inspection.

|

When finished selecting standards, click

Next Step.

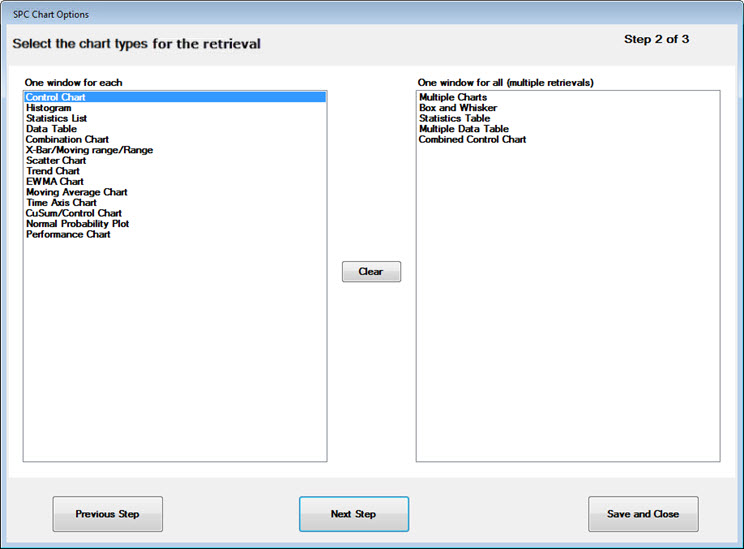

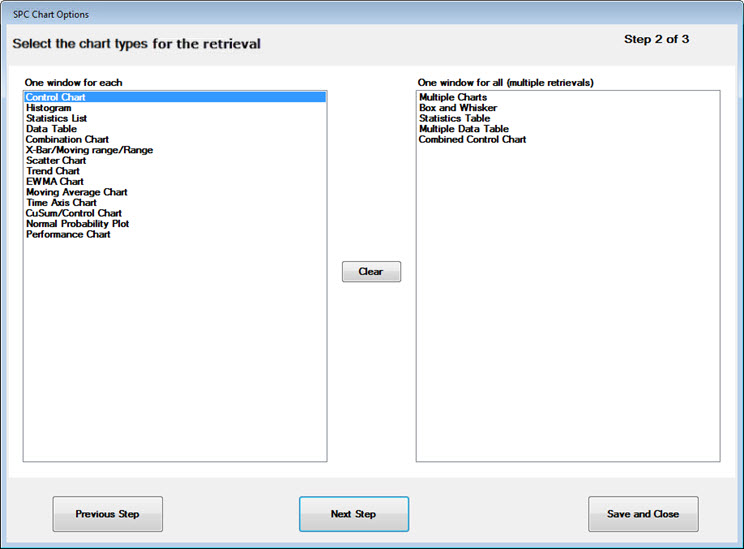

Step

2: Select chart types

Select

the SPC chart types you want to display, and then click Next

Step.

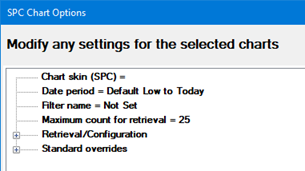

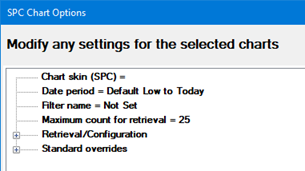

Step 3: Modify settings for the selected charts

Choose

retrieval and statistical settings for the standards and charts you

have selected. You can also specify a Chart

skin (created in the GainSeeker Charts module) that changes display

options for these charts. When finished, click Save

and Close.

Tip: If desired, you can configure

the charts with a special filter for data that matches traceability values

in this inspection:

Tip: If desired, you can configure

the charts with a special filter for data that matches traceability values

in this inspection:

Filtering for inspection traceability values

In some cases, you may wish to filter the

chart for a traceability value that was entered in this inspection – by a Traceability

test, Planned Inspection, or

Formula test (using inspect.cursubi.trace(idx).value or

inspect.settracevalue

Python commands).

For example, you might

wish to filter for:

To filter for such a traceability

value – which may

vary from one data entry session to the next –

you must create

a saved filter that looks for a blank value in that traceability field,

such as this example which filters for the current Cavity number:

Best practice: For this type of

traceability filter, best practice is to set this traceability value before launching the sub-inspection

that filters charts for that value. This is most easily accomplished by:

Best practice: For this type of

traceability filter, best practice is to set this traceability value before launching the sub-inspection

that filters charts for that value. This is most easily accomplished by:

requiring

the user to Submit the traceability value in a Traceability

test on a previous sub-inspection

removing this traceability field from the inspection

and using a Planned Inspection

to set the traceability value

removing

this traceability field from the inspection and using a Formula test to set the

traceability value with the Python command inspect.settracevalue.

(You can actually execute this Formula on the same sub-inspection

as the filtered charts by setting the FormulaMode

property to Pre.)

The reason for this recommended

practice is that the filter can only access a traceability value after that value has been submitted.

If the traceability value

is not set before the sub-inspection with the filter is launched, the

charts will be filtered for a blank value in this traceability field until

the sub-inspection is submitted with the new traceability value.

When new charts are

opened and updated during an inspection

When you use the ChartOptionsSPC

property of a sub-inspection to set up charts, the timing for creating

and updating those charts depends on how the standard for those charts

is defined.

Note: When the inspector submits

the sub-inspection data, all charts open in the right side panel refresh

for that sub-inspection. If you have multiple charts or charts containing

a lot of data open in the panel, this could prove time consuming.

Note: When the inspector submits

the sub-inspection data, all charts open in the right side panel refresh

for that sub-inspection. If you have multiple charts or charts containing

a lot of data open in the panel, this could prove time consuming.

Preset SPC standards

When a standard is selected using one

of these methods, the corresponding chart will be created immediately

when the sub-inspection opens:

When setting the sub-inspection

property ChartOptionsSPC,

the Part Number Source

is set to Select standard

from list

When setting the sub-inspection

property ChartOptionsSPC,

the Part Number Source

is set to Use numeric input

standard, and the selected Numeric

Input test meets one

of the following criteria:

The Numeric Input test has the SPCStandardSelection

property set to PickAheadOfTime

and the SingleSPCStandard

property set to a particular standard

Please note: If the SingleSPCStandard

property contains a value that does not match an existing

SPC standard, the inspection will still create a chart

with no data found for that standard

Please note: If the SingleSPCStandard

property contains a value that does not match an existing

SPC standard, the inspection will still create a chart

with no data found for that standard

A Planned Inspection

is used to select a different standard for the Numeric

Input test

The sub-inspection also contains a Formula

test with the FormulaMode

property set to Pre

and the PythonScript

property set to a script that uses the inspect.cursubi.ni(idx).partno

command to set a different standard

When the user submits the sub-inspection,

these charts will be updated to include the most recently-entered data.

SPC standards selected by the data entry

user:

When all

of the following criteria are met, the chart for a standard will be created

immediately after the data entry user selects the standard:

When setting the sub-inspection property ChartOptionsSPC,

the Part Number Source

is set to Use numeric input

standard

The Numeric Input test you select to be charted has

the SPCStandardSelection

property set to PickAtRuntime

If the user later selects a different standard

for the same Numeric Input test, a new chart will be added for the new

standard without removing the chart for the previous standard.

When the user submits the sub-inspection,

these charts will be updated to include the most recently-entered data.

When charts are closed during an inspection

Any of the following methods will close all

charts that are currently open in an inspection:

To close all charts when a sub-inspection

opens, set the sub-inspection property ClearSidePanel

to True

To close all charts when a Python

script finishes running, add the Python command inspect.cursubi.clearsidepanel

= True to your script

Close the inspection

Please note: Closing a sub-inspection

does not close the charts that are currently open.

Please note: Closing a sub-inspection

does not close the charts that are currently open.

Sending emails with charts during an inspection

Note: If you copy and paste

a sub-inspection that is configured to chart one or more numeric

input standards, you will need to re-select the standards for

these charts in the new copy of the sub-inspection. This is because

the numeric input tests in the new sub-inspection will have different

TestIDs from those in the original sub-inspection. A reminder

message will be displayed when you copy and paste such a sub-inspection.

Note: If you copy and paste

a sub-inspection that is configured to chart one or more numeric

input standards, you will need to re-select the standards for

these charts in the new copy of the sub-inspection. This is because

the numeric input tests in the new sub-inspection will have different

TestIDs from those in the original sub-inspection. A reminder

message will be displayed when you copy and paste such a sub-inspection.