Overpack reduction examples

The GainSeeker Charts Overpack Wizard is a useful tool for determining if overpack levels in your processes could safely be reduced. A shift in process or reduction in variation could minimize the overpack in your process, saving a substantial amount of money over time.

Using the wizard will not actually change your processes, it only demonstrates what you could possibly achieve using various scenarios. What you decide to implement in your processes is your decision based on your company's unique requirements and some process circumstances. Always exercise caution when making changes to a process so it does not result in tampering or unexpected results.

Using the wizard will not actually change your processes, it only demonstrates what you could possibly achieve using various scenarios. What you decide to implement in your processes is your decision based on your company's unique requirements and some process circumstances. Always exercise caution when making changes to a process so it does not result in tampering or unexpected results.

Realizing process optimization

Potential process optimization can only be realized when:

and

-

the lower boundary of the Sigma safety factor (risk) moves left toward—but not past—the Minimum Value (or the Label – [minus] MAV [Maximum Allowable Variance] in the foods industry).

-

See an Example of this below.

The amount by which you can potentially optimize your process for a standard is whichever of these scenarios first proves to be the limiting factor in your shift.

Example: A shift in Mean toward the Target (or label weight) is the limiting factor

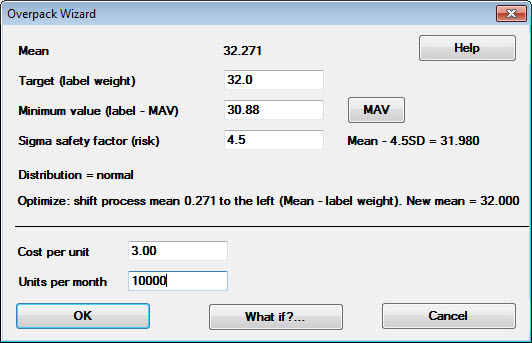

Tip: You can click the MAV button on the Overpack Wizard to open a reference table that lists Maximum Allowable Variations (MAVs) for Packages Labeled by Weight. Click the Help button for general information about using the Overpack Wizard.

Tip: You can click the MAV button on the Overpack Wizard to open a reference table that lists Maximum Allowable Variations (MAVs) for Packages Labeled by Weight. Click the Help button for general information about using the Overpack Wizard.

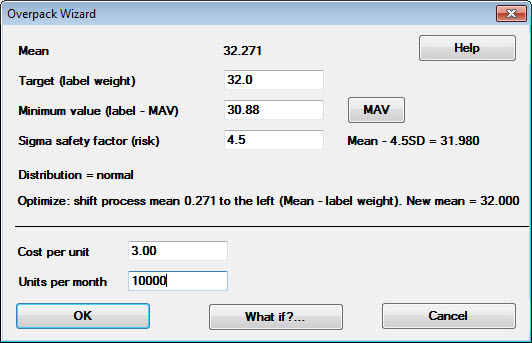

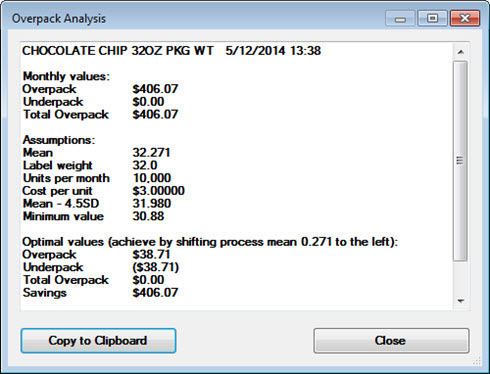

Fig. 1

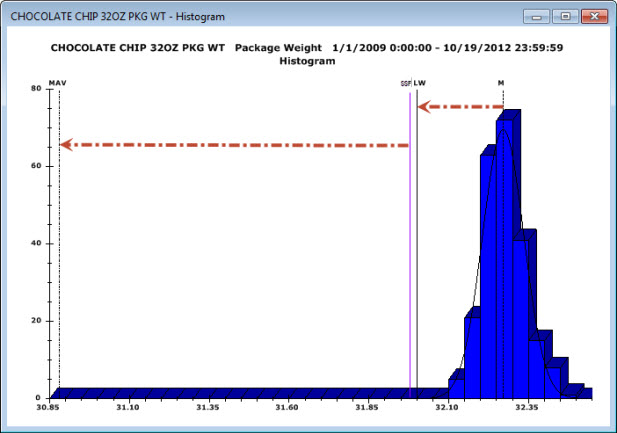

For the standard chocolate chip 32 oz pkg wt, the optimized value calculation suggests a 0.271 shift to the left (see Fig. 1):

- the Mean—M—will meet the Target (label weight)—LW—before the Sigma Safety Factor (Risk)—SSF—can meet the Label – (minus the) MAV— MAV. (See Fig. 2)

This means that the shift of the Mean toward the Minimum Value (or Label – MAV for foods) is the limiting factor and where process optimization may be possible.

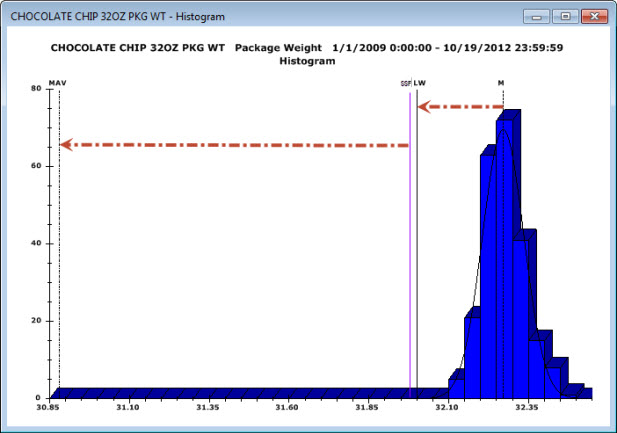

Fig. 2

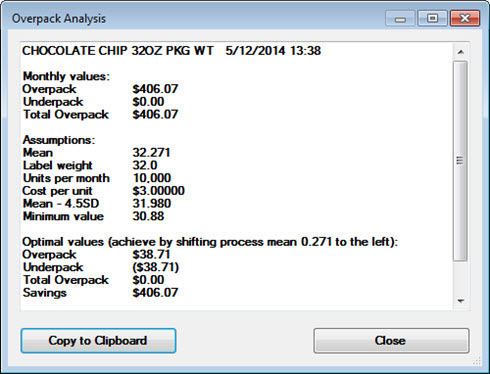

Fig. 3: Calculations using the 0.271 shift diagrammed in Fig. 2 show that $406.07 in monthly savings could be realized for this standard.

Example: A Sigma safety factor (risk) shift toward the Minimum Value (or Label – MAV) is the limiting factor

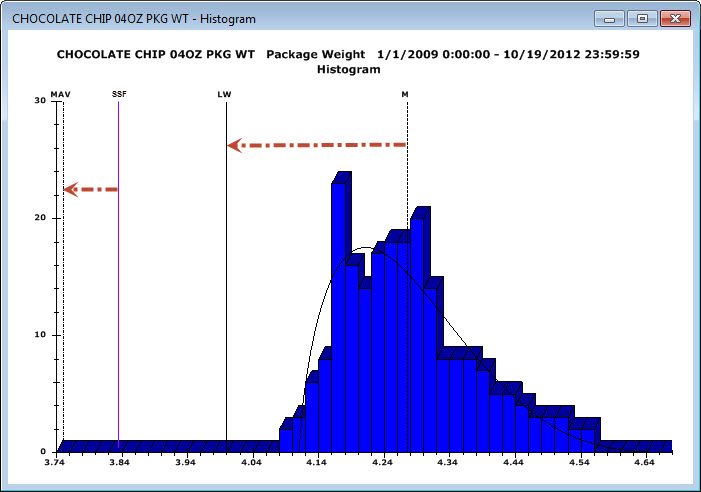

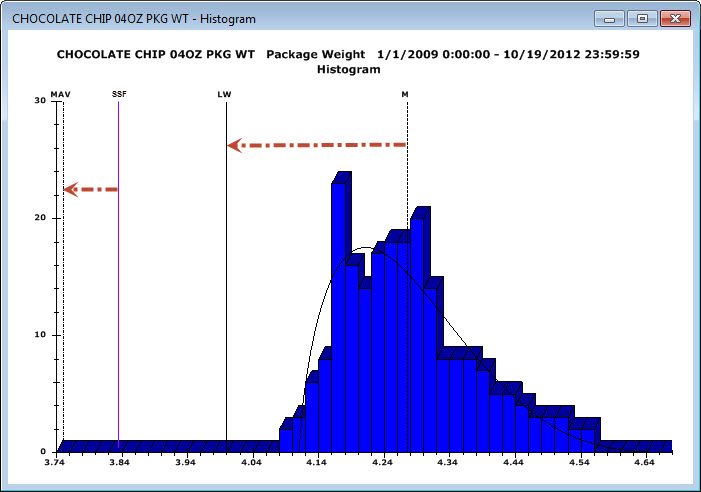

Fig. 4

For the standard (Fig. 4) chocolate chip 04 oz pkg wt, in a suggested 0.076 shift to the left (see Fig. 5):

- The Sigma Safety Factor (Risk)—SSF—will meet the Label – (minus) MAV—MAV—before the Mean—M—will meet the Target (label weight)—LW. (See Fig. 5)

This means that the shift of the Sigma Safety Factor (Risk) toward the Minimum Value (Label – MAV) is the limiting factor and where process optimization might be possible. However, this might be a good scenario for experimenting with the What if?... button on the Overpack Wizard to determine the amount of money you could save by reducing the variation by n% and shifting the Mean closer to the Target (or label weight), thereby shifting the process.

Fig. 5

The Overpack Analysis for this standard shows a $114.25 monthly savings (Fig. 6) in shifting the Sigma Safety Factor (Risk) toward the Minimum Value (Label – MAV).

Fig. 6

Using the wizard will not actually change your processes, it only demonstrates what you could possibly achieve using various scenarios. What you decide to implement in your processes is your decision based on your company's unique requirements and some process circumstances. Always exercise caution when making changes to a process so it does not result in tampering or unexpected results.

Using the wizard will not actually change your processes, it only demonstrates what you could possibly achieve using various scenarios. What you decide to implement in your processes is your decision based on your company's unique requirements and some process circumstances. Always exercise caution when making changes to a process so it does not result in tampering or unexpected results. Tip: You can click the

Tip: You can click the