You can define the Overpack Wizard default values you want to associate with a standard for the analysis.

Use the Standard Information dialog to enter the following values for a standard:

the Per-item or per-package cost

the Quantity produced in one month of that standard

the Target (Label weight)

the Minimum Value (or the Label – MAV [Maximum Allowable Variation] for foods).

The values you enter for a standard on the Standard Information dialog will automatically display any time you perform an analysis for that standard using the Overpack Wizard . This will prevent you from having to enter these values on the wizard each time you use it.

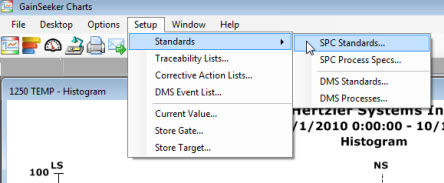

Click the Setup menu on the GainSeeker Charts window, point to Standards, and then click SPC Standards... on the submenu that displays.

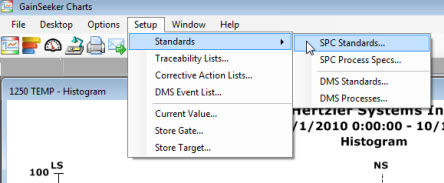

The Select Part Number dialog opens:

Click a standard in the list to select it. Then, click Edit... .

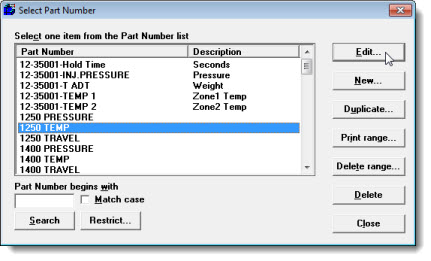

The Standard Information dialog opens.

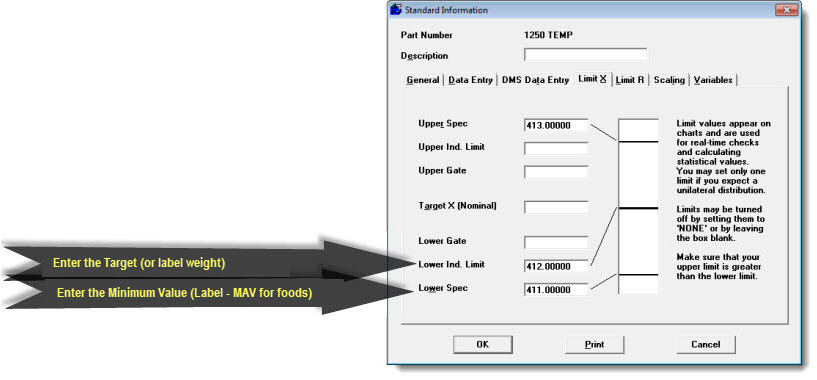

Use the Limit X tab to define values for the Target (Label weight) and the Minimum Value (or the Label – MAV for foods).

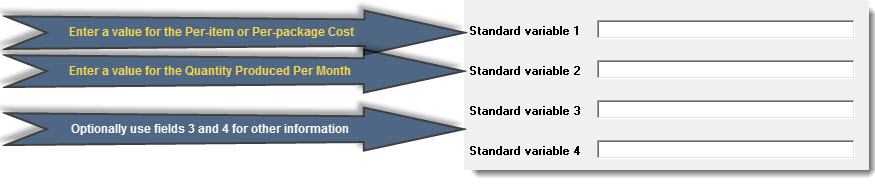

Use the Variables tab to define values for the Per-item or Per-package Cost and the Quantity Produced per month of that standard.

Fig. 1

On the Limit X tab of the Standard Information dialog:

Depending on your type of standard, the Target (Label weight) value will be:

In the foods industry:

(Label weight): This is the stated weight or volume on the package label. For example, for a standard such as a package of cookies labeled 16.0 ounces, you would enter 16.0 in this field.

In other industries:

Target: This is the goal you set for each data point. For example, if you are applying a paint coating to your product and your goal is to maintain a .32-inch thickness of paint on each part, you would enter .32 in this field.

On the Limit X tab of the Standard Information dialog:

Enter the Minimum Value in the Lower Spec text box as shown in Fig. 1 above (This label may be different depending on your settings.).

Depending on your type of standard, the Minimum Value will be:

In the foods industry:

It is the Label minus the Maximum Allowable Variance (MAV) for that standard—the allowable deviation from the package label weight.

In other industries:

It is the minimum line (the bottom boundary) at which a data point can plot. For example, if you are applying a paint coating to your product and your goal (target) is to maintain a .32-inch thickness of paint on each part, but a .308-inch thickness is the allowable thinnest (minimum) it can be, you would enter .308 in this field.

Also see Defining the per-item or Per-package Cost and the Quantity Produced Per Month, which follows in this topic.

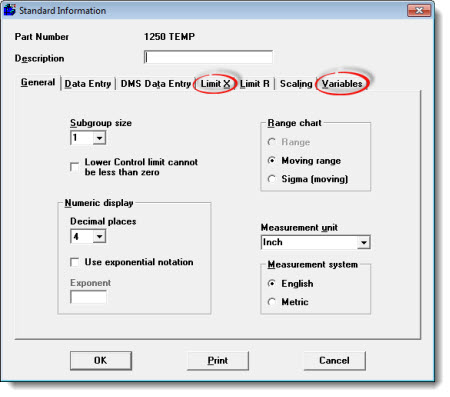

Fig. 2

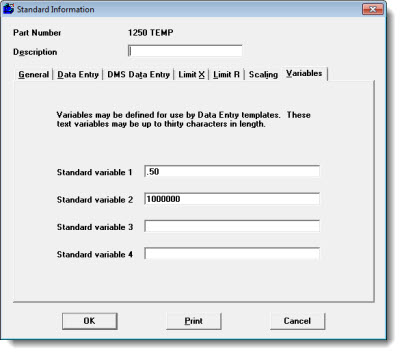

On the Variables tab of the Standard Information dialog:

Enter the Per-item or Per-package (production) Cost of your standard in the Standard variable 1 text box as shown in Fig. 2 above. For example, if the production cost of your standard is fifty cents, you would enter .50 .

On the Variables tab of the Standard Information dialog:

In this example for Part Number (standard) 1250 TEMP, Standard variable 1—the per-item or per-package cost—is set to .50 . Standard variable 2—the quantity produced per month—is set to 1000000 (one million).

Also see Defining the Target (Label weight) and the Minimum Value (or the Label –MAV for foods) above in this topic.

See Overpack Wizard for more information.

To create and edit SPC standards you want to analyze: