Save time and money by tapping into the data you already own

More than likely, you are not lacking in data. You’re probably deluged with it. But most of this data is inaccessible and unusable. And it is getting worse. (See our ebook, Tripping Over Data.) There are estimates that 70% of the data generated in a manufacturing company is never used, or is under-utilized. That is a huge waste of a valuable corporate asset.

GainSeeker Suite provides integration capabilities to make it easy to connect to almost any data source, including:

- Digital gages such as Mitutoyo, Starrett, and Fowler

- Weigh scales such as Ohaus and Sartorius

- CMM and Visions systems such as Keyence, Brown & Sharp, Nikon, Zeiss, and Omron

- IoT data from sensors and equipment such as Schneider Electric, GE, Emerson, Matrikon, and Kepware

- MES Systems such as Aspen Tech, Dassault Systemes, Cognizant, and Epicor

- EQMS Systems such as EtQ and IQS

- ERP Systems such as Oracle, SAP, and Epicor

- SharePoint

But most of this data is inaccessible and unusable. And it is getting worse. (See our ebook, Tripping Over Data.) There are estimates that 70% of the data generated in a manufacturing company is never used, or is under-utilized. That is a huge waste of a valuable corporate asset.

GainSeeker data entry and integration is powered by our vast library of existing integration scripts. These can be tailored to your exact needs. Or your team can easily extend these connections using Python® scripts.

Hertzler staff can collaborate with your team in the way that makes the most sense for your business. We can provide turnkey operations, or coaching and advising services. Our goal is always to empower your team so you can adapt and flex as your business evolves and grows.

GainSeeker analytics, connected to all of this data, makes it easier to take advantage of the data that is in your company. And GainSeeker visualization makes sure all stake holders are in the know.

This enables your team to make better, more timely decisions to improve quality, profitability, and customer experience.

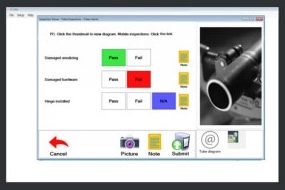

Real-time defect inspection