The OEE metric is calculated from the percentages of three submetrics: Availability, Performance, and Quality.

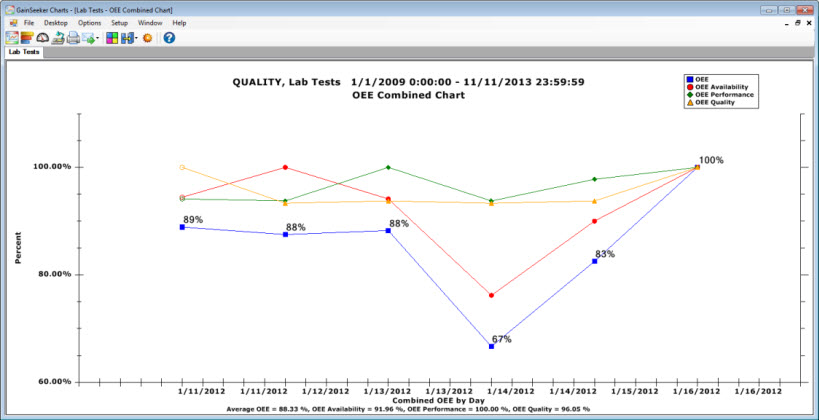

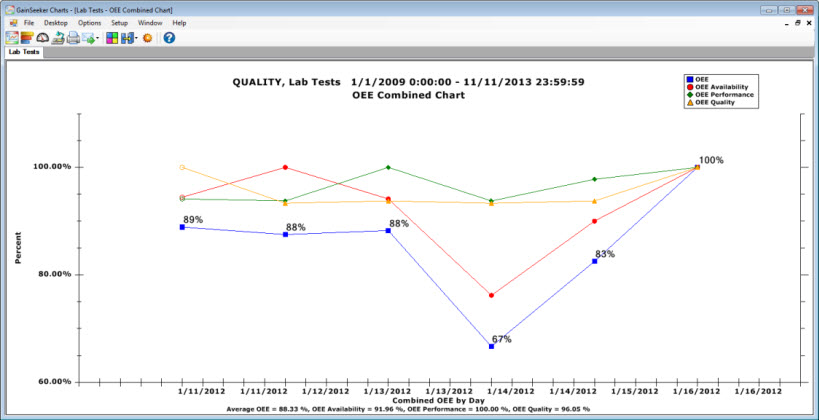

Example of an OEE Combined chart that displays the overall OEE metric and its submetrics:

Availability = 75.1%

Performance = 87.8%

Quality = 89.8%

OEE = Availability (75.1%) x Performance (87.8%) x Quality (89.8%)

OEE = 59.2%

To see how each of these metrics was calculated for this example, see:

It can be misleading to compare OEE numbers between manufacturers, or from plant to plant within the same company because no two plants, products, equipment, or human assets are identical. A good use for OEE numbers then is to establish baseline percentages for your organization and work to improve them—without comprising first-pass yield.

Following are OEE percentages that are typically considered to be good.

Availability 90%

Performance 95%

Quality 99.9% (may be low for some Six Sigma initiatives)

Overall OEE 85%+ for World Class Manufacturing (60% is average).

Examples of OEE Charts